Toyota is committed to taking another step forward in the development of hybrid and electric vehicles. Discover a new system that uses Silicon Carbide in the construction of power controller modules, with promises of greater efficiency.

Toyota has been one of the brands that has invested the most in the development of alternative technologies for hybrid vehicles, together with Denso, in a partnership that has lasted for a respectable 34 years.

As a result of this research, Toyota now presents a new generation of power controller modules (PCU) – which are the operations center in these vehicles – using one of the hardest materials on the face of the earth: Silicon Carbide (SiC) .

Through the use of Silicon Carbide (SiC) semiconductors in the construction of PCU's – in detriment of traditional silicon semiconductors – Toyota claims that it is possible to improve the autonomy of hybrid and electric vehicles by around 10%.

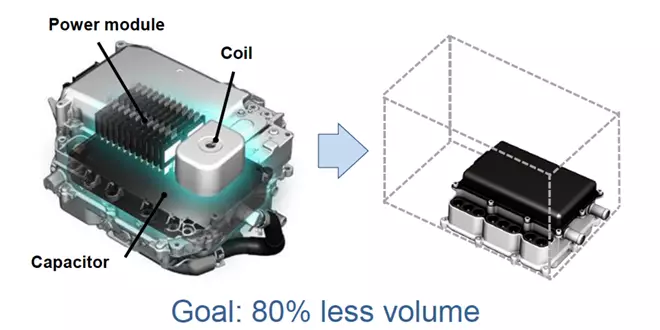

It may be a marginal advantage, but it should be noted that SiC conductors are responsible for power losses of only 1/10 during the current flow, which allows to reduce the size of components such as coils and capacitors by about 40%, representing an overall 80% reduction in PCU size.

For Toyota, this is especially important since the PCU alone is responsible for 25% of energy losses in hybrid and electric vehicles, with PCU semiconductors accounting for 20% of total losses.

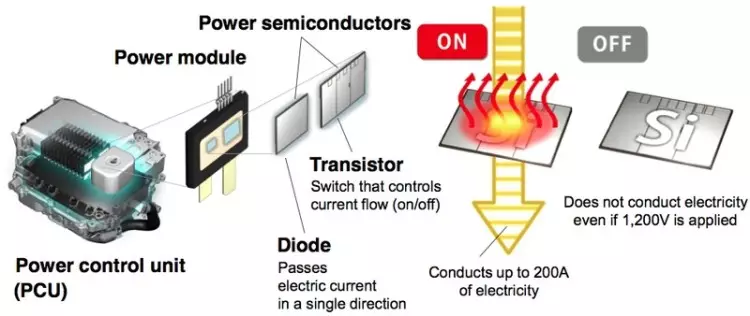

The PCU is one of the most vital components in hybrid and electric vehicles, because it is the PCU that is responsible for supplying the electric current from the batteries to the electric motor, for controlling the rotation of the electric motor, for managing the regeneration and recovery system. energy, and finally, by switching the operation of the electric motor between the propulsion unit and the generating unit.

Currently, PCU's are made up of several electronic elements, the most important of which turn out to be the various silicon semiconductors, with different electrical strengths and resistances. It is precisely in the semiconductor technology applied in the PCU that this new Toyota technology comes into play, which are more efficient in three decisive fields: energy consumption, size and thermal properties.

Toyota knows that while batteries with a more advanced technology with high energy density do not appear, which can perfectly combine remarkable values of (Ah and V), the only resource from which it will be able to increase energy efficiency is to make all electrical components that are part of electronic management more efficient and resistant.

Toyota's future with these new drivers is promising – despite production costs still being 10 to 15 times higher than conventional ones – given the partnerships already reached in the massification of these components and the tests already carried out on the road with gains of 5% in the minimum guaranteed. Watch through the video, the revolution that silicon carbide semiconductors perform: