At Martorell, SEAT's headquarters, quality tests are carried out down to the smallest detail, in particular the body paint.

It is not just on track or on off-road circuits that quality tests are carried out on a model. Much of the analysis of the quality and durability of materials is carried out in the laboratory, and in the case of SEAT, these tests are carried out in Martorell, headquarters of the Spanish brand.

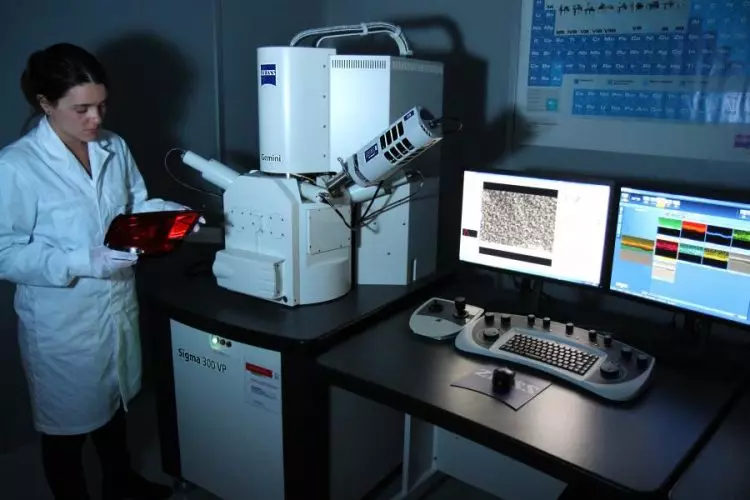

In the quality department at SEAT an electron microscope capable of magnification of up to 100,000 times is used. Any type of material used in an automobile can be analyzed under this microscope: metals, fabrics, plastics or paint. The purpose of these tests is to confirm the absence of impurities impossible to detect with the naked eye and thus extend the durability of the components.

As an example, the analysis of the different layers of paint (each with less than 0.12 millimeters), in addition to helping to prevent the fading of pigments over the years, helps to prevent them from chipping with the projection of gravel, among others.

PREVIEW: Majorca? Vigo? Formentor? What will the new SEAT SUV be called?

Microscopic analysis also ensures that the different parts of the car have the same hue and shade and that, when fully assembled, all components and panels combine in harmony. Although the perception of color is somewhat subjective, thanks to scientific assessment it is possible to verify that the bumpers, doors and bonnet are exactly the same shade.

Due to the fact that light conditions vary in different countries, this technology ensures that colors will always have the hues that were idealized and that they will remain bright for longer periods of time.