Ford has a long tradition of producing innovative gasoline engines. Who does not remember the Sigma engines (commercially known as Zetec) that in the 1.25 l, 1.4 l, 1.6 l and 1.7 l displacements delighted fans of the blue oval brand in models such as the Ford Fiesta, the Puma or even the Focus?

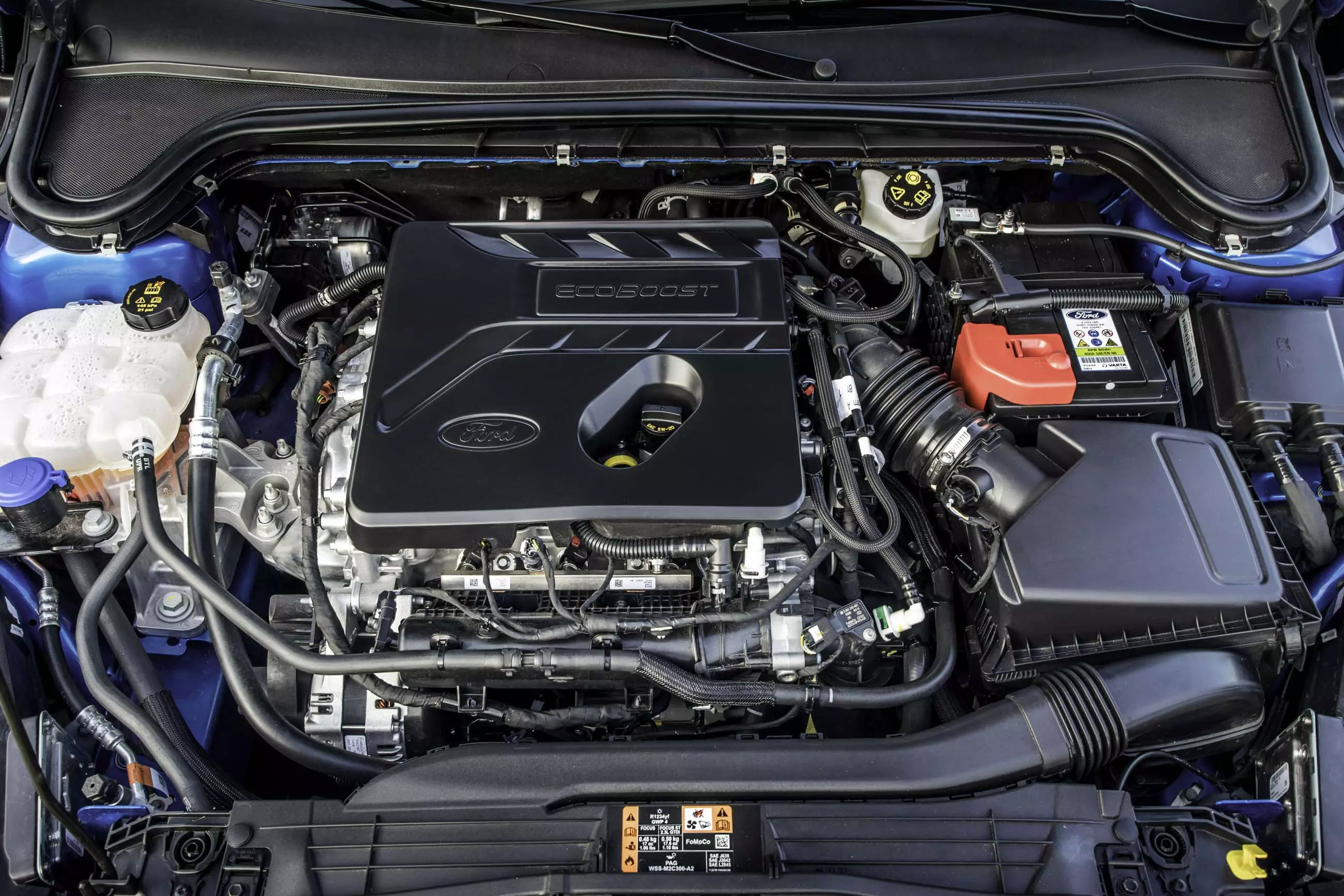

It is not surprising that given Ford's ability to produce innovative gasoline engines, the EcoBoost family of engines has emerged, combining efficiency with performance, using supercharging, high-pressure direct fuel injection and dual variable opening control. valves (Ti-VCT).

EcoBoost is now synonymous with a large family of powertrains at Ford , ranging from large and powerful V6s, like the one that equips the Ford GT, to a small three-cylinder in-line, which despite its compact size, ended up becoming the crown jewel of this mechanical family.

1.0 EcoBoost: the egg of Columbus

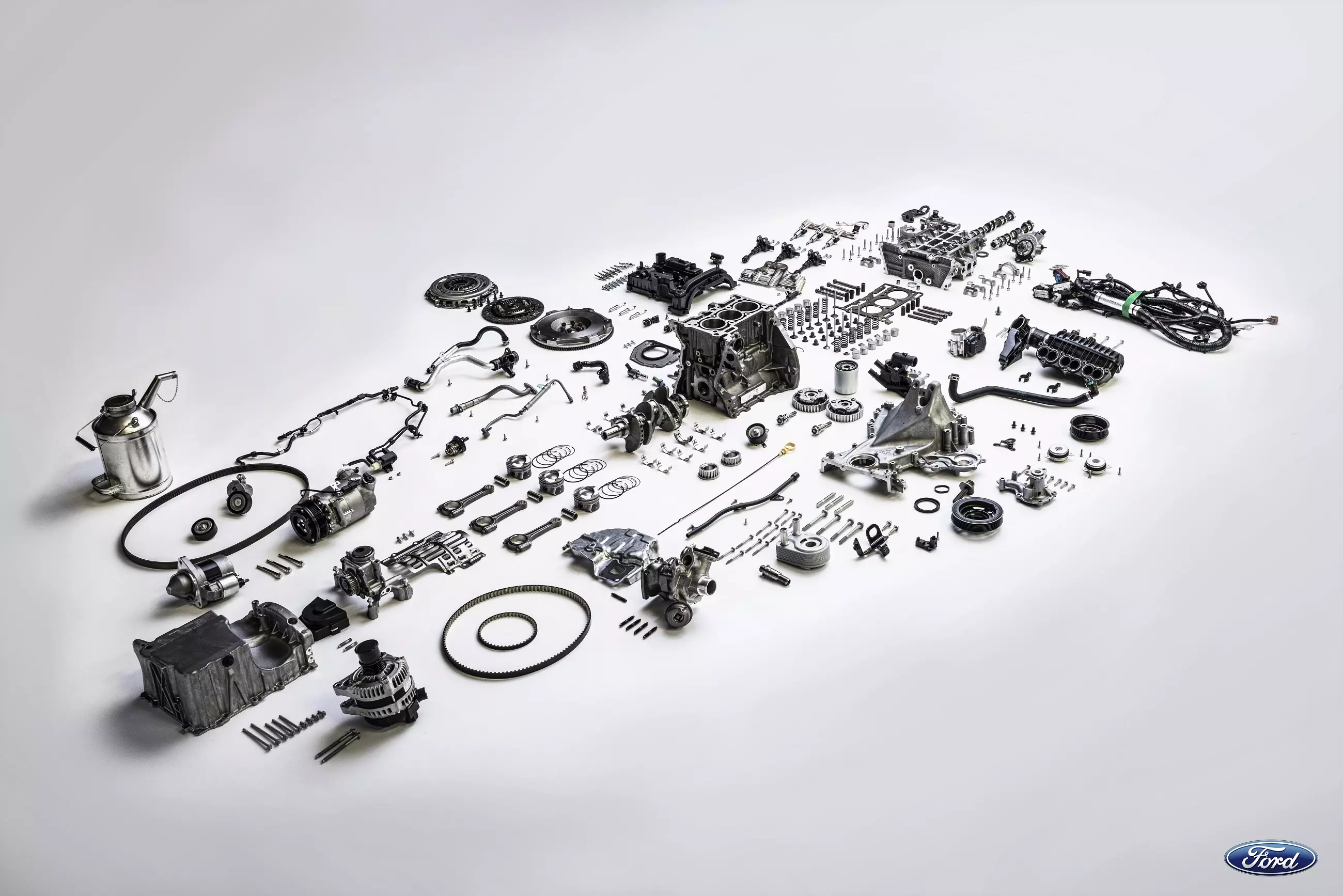

To create the three-cylinder 1.0 EcoBoost, Ford spared no effort. It's a compact engine, so compact that the area occupied by the pad is on the limits of an A4 sheet of paper . To prove its reduced dimensions, Ford even transported it, by plane, in a small suitcase.

This engine first appeared in the Ford Focus in 2012 and has since been extended to many other models in the Ford range. The success was such that by mid-2014 already one in five Ford models sold in Europe was using the three-cylinder 1.0 EcoBoost.

One of the keys to its success is its low-inertia turbocharger, capable of rotating up to 248,000 revolutions per minute, or more than 4000 times per second. Just to give you an idea, it's about twice the revs of the turbos used in Formula 1 in 2014.

The 1.0 EcoBoost is available in various power levels — 100 hp, 125 hp and 140 hp, and there's even a 180 hp version used in the rallying Ford Fiesta R2.

In the 140 hp version the turbo provides a boost pressure of 1.6 bar (24 psi). In extreme situations, the pressure exerted is 124 bar (1800 psi), that is, the equivalent of the pressure exerted by a five-ton elephant placed on top of a piston.

unbalance to balance

But the innovations of this engine are not only made from the turbo. Three-cylinder engines are naturally unbalanced, however, Ford engineers decided that to improve their balance, it was best to intentionally unbalance them.

By creating an intentional imbalance, when in operation, they were able to balance the engine without having to resort to so many counterweights and engine mounts that would only add to its complexity and weight.

We also know that to improve consumption and efficiency, the ideal is for the engine to warm up as quickly as possible. To achieve this, Ford decided to use iron instead of aluminum in the engine block (which takes about 50% less to reach the ideal operating temperature). In addition, engineers installed a split cooling system, which allows the block to heat up before the cylinder head.

First three cylinders with cylinder deactivation

But the focus on efficiency didn't stop there. In order to further reduce consumption, Ford decided to introduce cylinder deactivation technology in its smallest propeller, an unprecedented feat in three-cylinder engines. Since the beginning of 2018, 1.0 EcoBoost has been able to stop or restart a cylinder whenever its full capacity is not needed, such as on downhill slopes or at cruising speeds.

The entire process of stopping or restarting combustion takes just 14 milliseconds, that is, 20 times faster than the blink of an eye. This is achieved thanks to sophisticated software that determines the optimal time to deactivate the cylinder based on factors such as speed, throttle position and engine load.

To ensure that running smooth and refinement were not affected, Ford decided to install a new dual-mass flywheel and a vibration-dampened clutch disc, in addition to new engine mounts, suspension shafts and bushings.

Finally, to ensure that efficiency remains at the level of consumption, when the third cylinder is reactivated, a system contains the gases to ensure that temperatures inside the cylinder are maintained. At the same time, this will ensure a spring effect that helps balance the forces across the three cylinders.

Awards are synonymous with quality

Attesting to the quality of the smallest engine in the EcoBoost family are the numerous awards it has won. For six consecutive years, the Ford 1.0 EcoBoost has been named “Engine of the Year 2017 International – “Best Engine Up to 1 Liter””. Since its launch in 2012 the small engine has raked in 10 International Engine of the Year trophies.

Of these 10 awards won, three went to the general (a record) and another was for “Best New Engine”. And don't think it's an easy task to be nominated, let alone win one of these trophies. To do so, the small three-cylinder Ford had to impress a panel of 58 specialist journalists, from 31 countries, in 2017 had to wrestle with 35 engines in the 1.0 l three-cylinder category.

Currently, this engine can be found in models such as the Ford Fiesta, Focus, C-Max, EcoSport and even in the Tourneo Courier and Tourneo Connect passenger versions. In the 140 hp version this engine has a specific power (horses per liter) higher than that of a Bugatti Veyron.

Ford continues to bet on three-cylinder engines, with a 1.5 l variant used in the Focus and Fiesta that achieves powers of 150 hp, 182 hp and 200 hp.

The EcoBoost family also includes in-line four-cylinder and V6 engines — the latter, with 3.5 l, delivering 655 hp in the aforementioned Ford GT, and 457 hp in the radical F-150 Raptor pick-up.

This content is sponsored by