Whenever we speak of "mechanical nobility", we never speak of engines with less than six cylinders. Have you ever wondered why? The answer is as simple as it is complex. “Balance” is the key word in this symphony of pieces that rotate at more than 7000 revolutions per minute.

Engines with six cylinders (or more), regardless of the architecture chosen, are naturally more balanced than their counterparts with only four cylinders (or less). That's why its functioning is more refined and… nobler!

In four-cylinder in-line engines the pistons are 180° out of phase. That is, when rams one and four are going up, rams two and three are going the opposite way. However, the movements do not overlap, causing an imbalance of masses that translate into vibrations.

Manufacturers try to offset these imbalances with counterweights, flywheels, etc., but it is never possible to achieve the results of a six-cylinder (or more) engine.

In this regard, we have two dominant architectures: the six-cylinder in-line engines and the six-cylinder V-engines.

In the in-line six-cylinder engine, the pistons are arranged in the crankshaft at 120° intervals and are even numbered (6). Therefore, each plunger has a "twin" moving in the opposite direction, canceling out the imbalance and reducing vibrations. Along with the V12s, the six inline cylinders are the most balanced and smoothest in operation when it comes to piston engines.

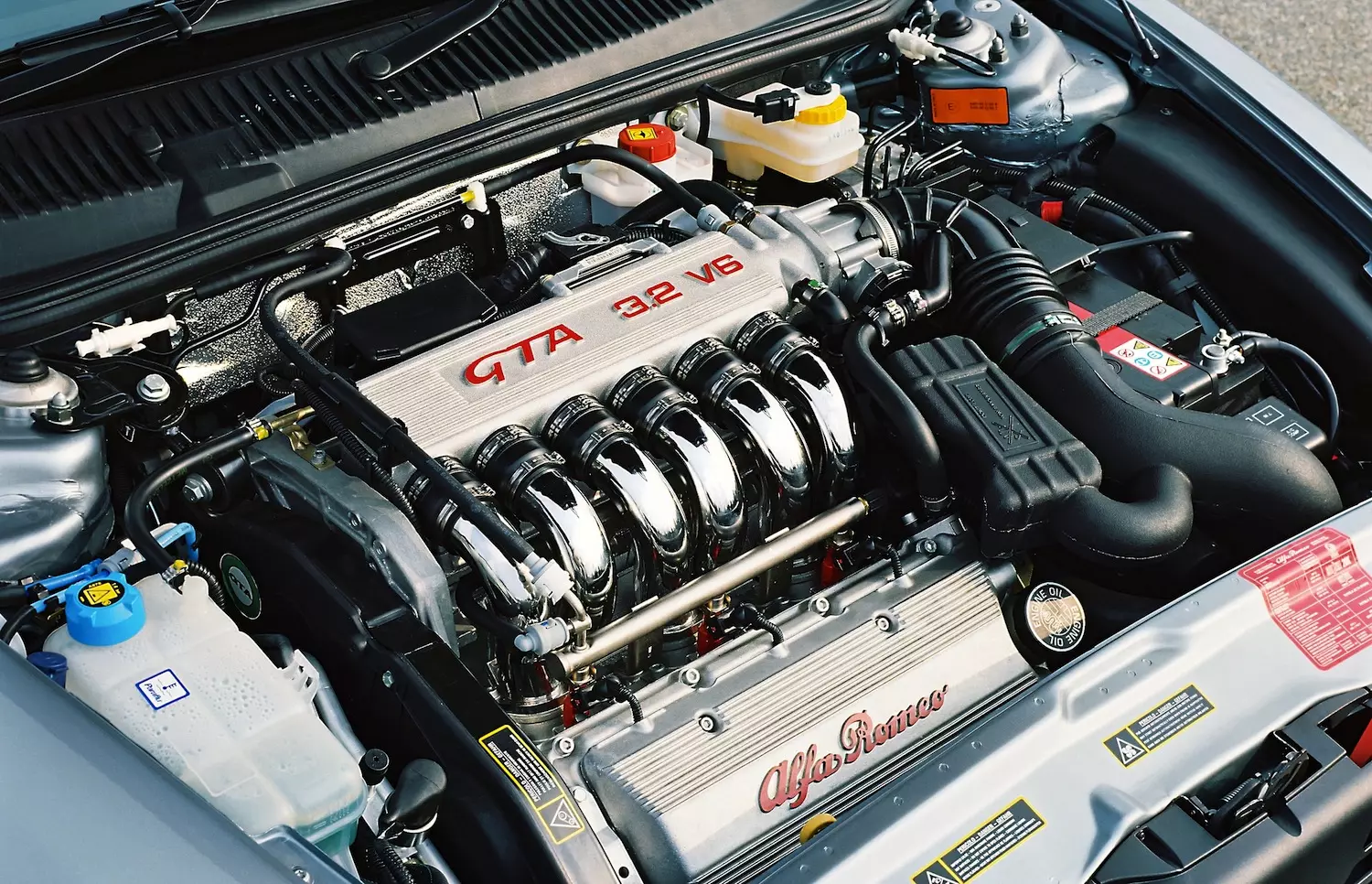

Despite having the same number of cylinders, V6 engines, by dividing the cylinders into two in-line three-cylinder benches each (an architecture known for its imbalance), do not achieve such good primary balance.

Subscribe to our newsletter

The angle of the V between the two stands can vary, the most common being 60º or 90º, with the former being more balanced than the latter. The 90º ones, as a rule, derive from V8 engines (an angle that favors the balance of this type of engine) — see the case of the V6 that equip the Quadrifoglio of Alfa Romeo and the new Nettuno of Maserati, or even the V6 of the Group Volkswagen, which equip models of Audi and Porsche.

Over the past 20 years, several brands have sworn "love oaths" to V6 engines. More compact ("fitting them" even in the most common front-wheel drive architecture with engines in a transverse position is easier) and powerful, all seemed to surrender to their advantages. But now many are returning to the 'classic' six in a row.

Why? It is the answer that we will try to find in this SPECIAL from Reason Automobile.

Costs, costs and more costs

V6 engines are more expensive to produce. Double everything! Instead of two camshafts for six cylinders, we have four camshafts (two per bench). Instead of having just one cylinder head, we have two cylinder heads. Instead of a simple distribution system, we have a more complex distribution system.

But it's not just a question of the number of components. The advantages of in-line six-cylinder engines continue in other fields. Particularly in development.

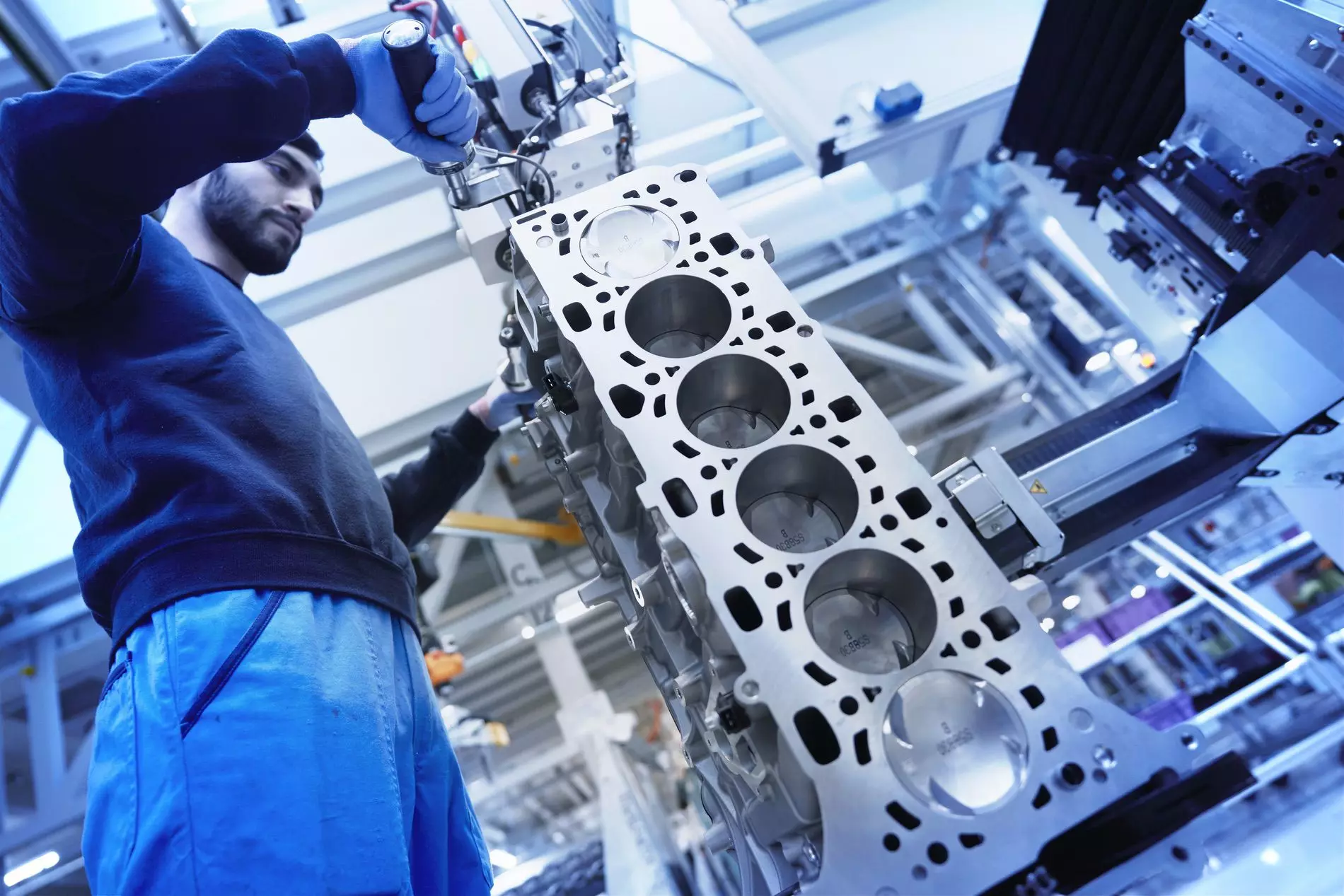

Take the example of BMW and its 'B-family' modular engines. Did you know the main mechanical components of the engine that powers the Mini One (three-cylinder engine and 1.5 l capacity), a BMW 320d (four cylinders and 2.0 l capacity) and a BMW 540i (six cylinders and 3 ,0 l capacity) are the same?

In a reductive and simplified way (very simplified indeed…) what BMW currently does is produce engines from modules of 500 cm3 each. Do I need a 1.5 liter three-cylinder engine for the MINI One? Three modules are joined. Do I need an engine for the 320d? Four modules come together. Do I need an engine for the BMW 540d? Yes you guessed. Six modules come together. With the advantage that these modules share most of the components, be it a MINI or a Series 5.

BMW 'B family' engines always share more than 40% of the components, irrespective of the number of cylinders or fuel (petrol or diesel). Look at this engine family as a LEGO. Several 500 cm3 blocks that can be put together in groups of three, four or six cylinders.

Thanks to this method, BMW has developed a family of engines that is capable of supplying the smallest MINI or the most aristocratic 7 Series. But don't think that BMW is unique. Mercedes-Benz and Jaguar, for example, have also adopted the same philosophy.

With V6 engines these component sharing would be impossible. Remarkable, don't you think?

Technical challenges the V6 can't overcome

A few years ago, when most V6 engines were atmospheric or used simple supercharging, the advantages of this architecture overlapped. Namely, the fact that they are more compact.

But as all engines turned to supercharging (the four turbocharged four cylinders of today took the place of the V6s that used to equip the “everything ahead” of yesteryear) and the treatment of exhaust gases became the order of the day, new challenges emerged.

In-line engines have the advantage of being able to assemble sequential turbos more easily. Another advantage concerns the treatment of exhaust gases. In in-line engines we only have two sides: intake and exhaust. This simplifies the way in which all the peripherals that concern combustion engines can be “tidy”.

It is for all these reasons (cost, complexity, technical necessity) that V6 engines are progressively disappearing.

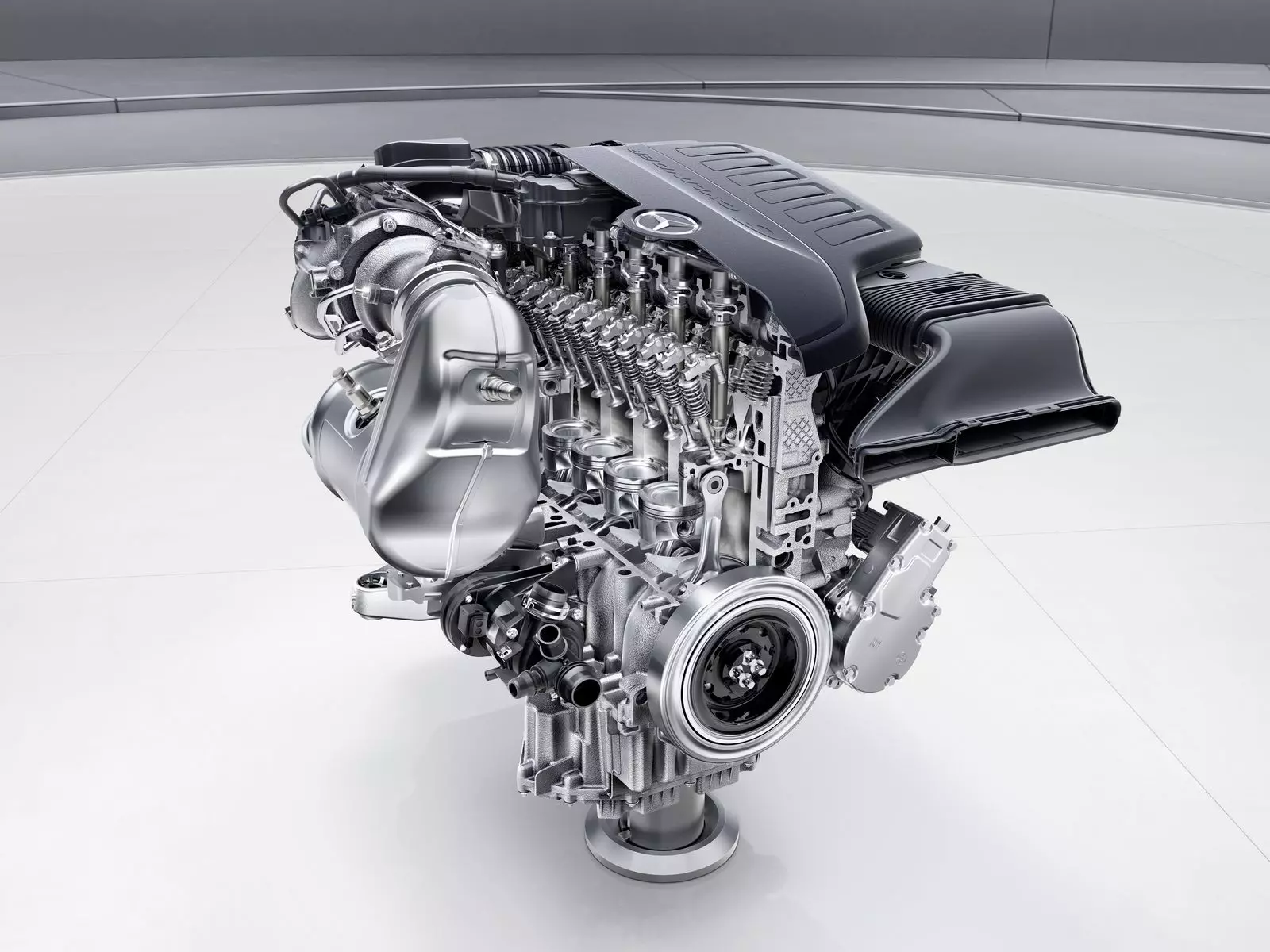

Mercedes-Benz has already abandoned them (M 256 has replaced the M 276), Jaguar Land Rover too — the Ingenium engine family, like the BMW engine family, is modular, with blocks of three, four and six in-line cylinders, with the latter already available in several Land Rover, Range Rover and Jaguar, both petrol and diesel. And more are on the way, like Mazda's inline six-cylinder duo, among others.

The evolution continues! For the delight of those who do not give up on the advantages and pleasures of combustion engines.

I WANT MORE ARTICLES ON AUTO TECHNIQUE