After Dieselgate definitively enveloped the Diesels in a dark cloud — we say “definitely”, because in fact, its end was already being debated more modestly before — now a suitable replacement is needed. Like it or not, the truth is that diesel engines were and continue to be the choice of a large majority of consumers. And no, it's not just in Portugal… Take this example.

Substitute: wanted!

It will be some time before electrification becomes the new “normal” for the car industry — it is estimated that in 2025 the share of 100% electric vehicles is still around 10%, which is not much.Therefore, until the arrival of this new “normal”, a solution is needed that offers the economy of use and the level of emissions of Diesel at the cost of purchasing gasoline engines.

What alternative is this?

Ironically, it's Volkswagen, the brand that was at the epicenter of the emissions quake, that comes up with an alternative to Diesel. According to the German brand, the alternative could be your new B-cycle engine. Thus adding one more type of cycle to those already existing in gasoline engines: Otto, Atkinson and Miller.

Cycles and more cycles

The best known is the Otto cycle, the most recurrent solution in the automotive industry. The Atkinson and Miller cycles prove to be more efficient at the expense of specific performance.

A gain (in efficiency) and a loss (in performance) due to the opening time of the inlet valve in the compression phase. This opening time causes a compression phase that is shorter than the expansion phase.

A part of the load in the compression phase is expelled by the inlet valve which is still open. The piston thus finds less resistance for the compression of gases — the reason why the specific efficiency is lower, that is, it results in less horsepower and Nm. This is where the Miller cycle, also known as the «five-stroke» engine, comes in. which, when resorting to supercharging, returns this lost charge to the combustion chamber.

Today, thanks to the increasing control of the entire combustion process, even Otto cycle engines are already able to simulate Atkinson cycles when loads are low (thus increasing their efficiency).

So how does cycle B work?

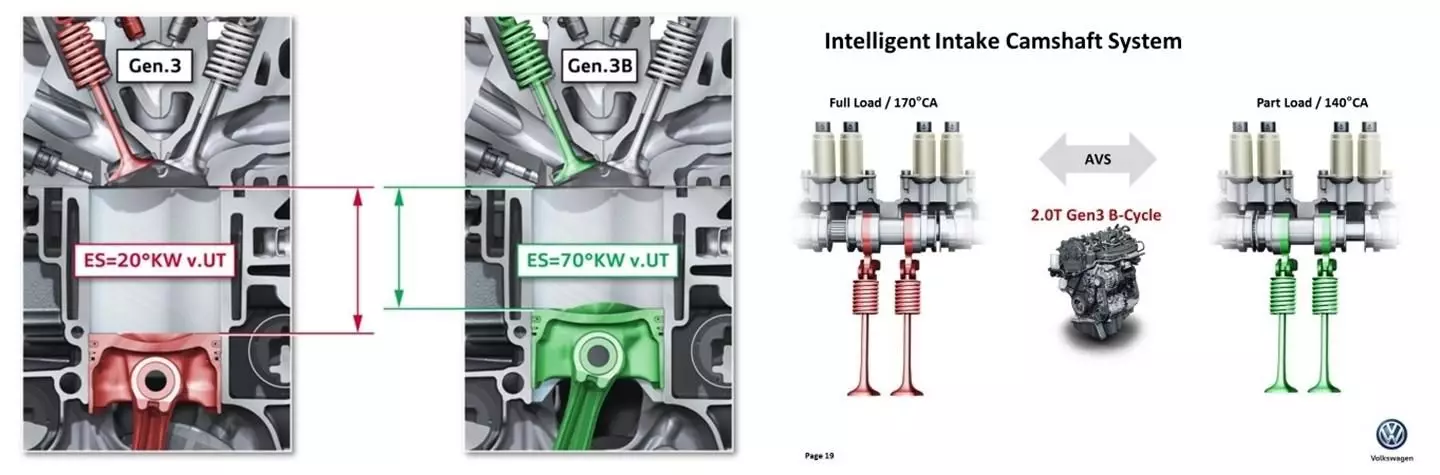

Basically, cycle B is the evolution of the Miller cycle. The Miller cycle closes the intake valves just before the end of the intake stroke. The B cycle differs from the Miller cycle in that it closes the inlet valves much earlier. The result is longer, more efficient combustion as well as faster airflow to the intake gases, which improves the fuel/air mixture.

One of the advantages of this new B-cycle is being able to switch to the Otto cycle when maximum power is needed, returning to the most efficient B-cycle during normal use conditions. This is only possible thanks to the axial displacement of the camshaft — which has two cams for each valve — allowing the opening times of the inlet valves to be changed for each of the cycles.

The starting point

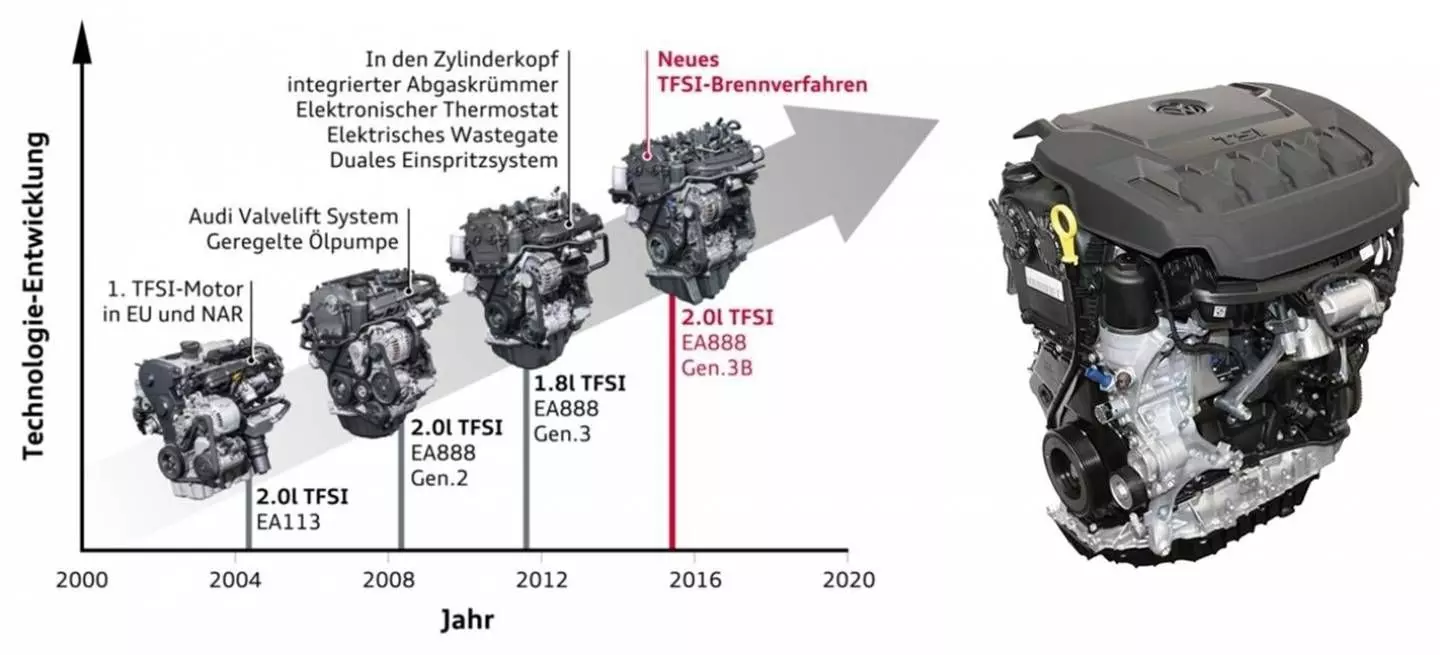

The EA888 engine was the starting point for this solution. Already known from other applications in the German group, it is a 2.0 l turbo engine with four cylinders in-line. This engine was mainly modified at the head level (it received new camshafts and valves) to work according to the parameters of this new cycle. These changes also forced the redesign of the pistons, the segments and the combustion chamber.In order to compensate for the shorter compression phase, Volkswagen raised the compression ratio to 11.7:1, an unprecedented value for a supercharged engine, which justifies the reinforcement of some components. Even the existing EA888 doesn't go beyond 9.6:1. Direct injection also saw its pressure increase, now reaching 250 bars.

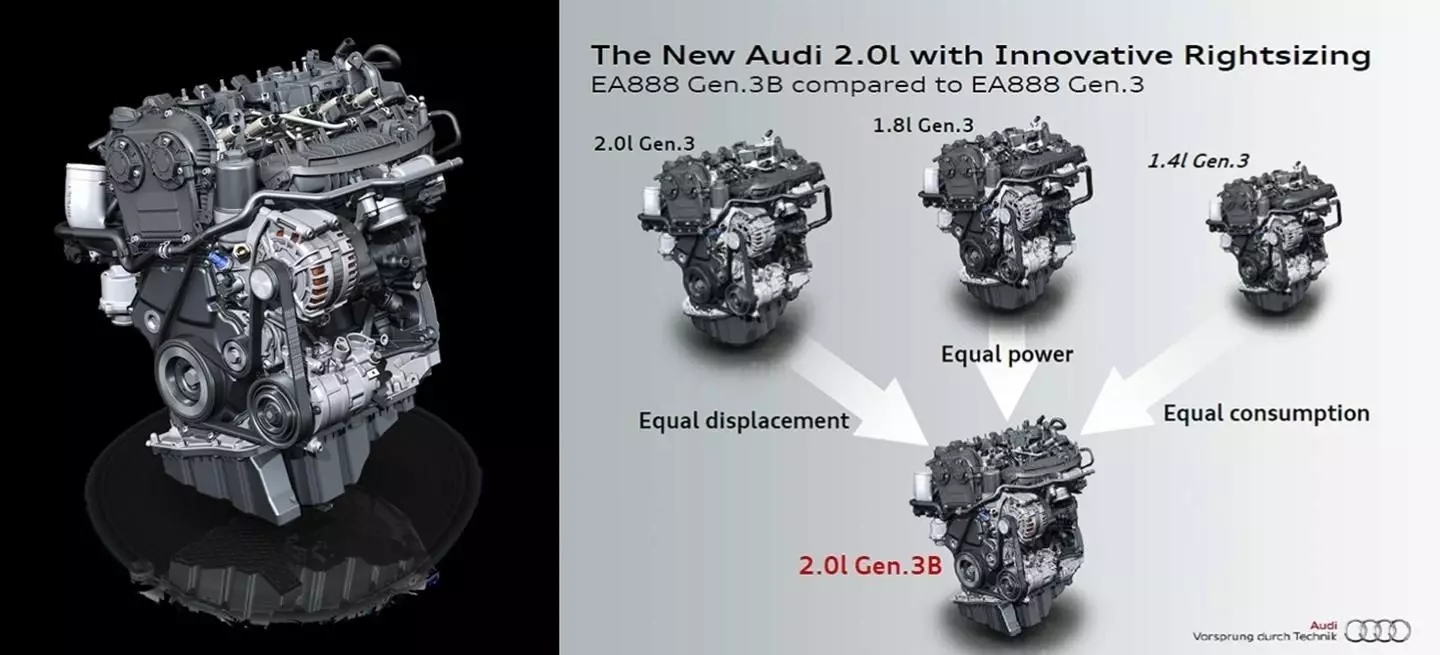

As an evolution of the EA888, the third generation of this engine family is identified as EA888 Gen. 3B.

let's go to numbers

The EA888 B maintains all four cylinders in line and 2.0 l of capacity, as well as the use of turbo. It delivers around 184 hp between 4400 and 6000 rpm and 300 Nm of torque between 1600 and 3940 rpm . This engine will initially aim to replace the 1.8 TSI that equips most models of the German brand that are sold in the North American market.

Downsizing for greater efficiency? Nor see him.

It will be up to the new Volkswagen Tiguan debut the new engine in the USA. According to the brand, the new 2.0 will allow better performances and lower consumption and emissions compared to the 1.8 which ceases to function.

At the moment, there are no official data regarding consumption. But the brand estimates a reduction in consumption of around 8%, a figure that could be substantially improved with the development of this new B-cycle.