In recent years, electronics has reached components that, until recently, we thought were entirely reserved for mechanics. The company's system Freevalve — which belongs to the business universe of Christian von Koenigsegg, founder of the hypercar brand with the same name — is one of the best examples.

What is the new?

Freevalve's technology manages to free combustion engines from the mechanical valve control system (we'll see with what benefits later). As we know, the opening of the valves is dependent on the mechanical movement of the engine. Belts or chains, connected to the engine crankshaft, distribute energy through the systems that depend on it (valves, air conditioning, alternator, etc.).

The problem with distribution systems is that they are one of the elements that most rob the engine of performance, due to the inertia created. And with regard to the control of camshafts and valves, as it is a mechanical system, the allowed operating variations are very limited (example: Honda's VTEC system).

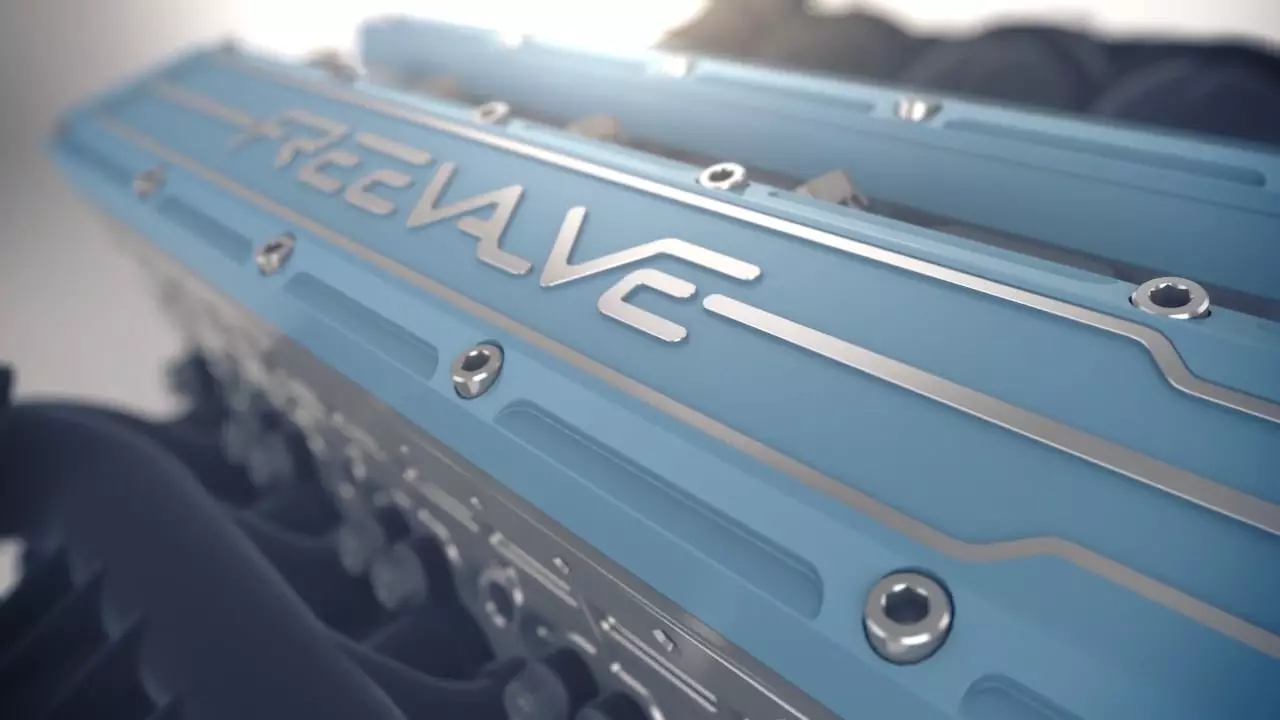

Instead of the traditional belts (or chains) that transmit their movement to the camshafts, we find pneumatic actuators

That said, we came to the conclusion that the merits of the system created by Christian von Koenigsegg's company are precisely the demerits of the systems present in current engines: (1) frees the engine from that inertia and (two) allows free management of valve opening times (intake or exhaust).

What are the advantages?

The advantages of this system are numerous. The first one we have already mentioned: it reduces the mechanical inertia of the motor. But the most important thing is the freedom it gives the electronics to control the opening time of the valves, depending on the engine speed and the specific needs of a given moment.At high speeds, the Freevalve system can increase the valve opening amplitude to promote a more homogeneous inlet (and outlet) of gases. At low speeds, the system can dictate a less pronounced opening of the valves to promote a reduction in consumption. Ultimately, Freevalve's system can even deactivate the cylinders in situations where the engine is not running under load (flat road).

The practical result is more power, more torque, greater efficiency and lower consumption. The gain in terms of engine efficiency can reach 30%, while emissions can be reduced by up to 50%. Remarkable, isn't it?

How it works?

In place of the traditional belts (or chains) that transmit their movement to the camshafts, we found pneumatic actuators (see video) controlled by the ECU, according to the following parameters: engine speed, piston position, throttle position, gear shift and speed.

Intake temperature and gasoline quality are other factors that can be taken into account when opening intake valves for maximum efficiency.

"With so many advantages, why is this system not yet commercialized?" you ask (and very well).

The truth is, this technology has been farther away from mass production. The Chinese from Qoros, a Chinese car maker, in collaboration with Freevalve, wants to launch a model with this technology as early as 2018. It may be an expensive technology, but we know that with mass production the values will decrease substantially.

If this technology confirms its theoretical benefits in practice, it could be one of the biggest evolutions in combustion engines — it's not the only one, see what Mazda is doing...