Today's most efficient gasoline engines achieve a thermal efficiency of 40% (most, however, are several percentage points below), but Nissan says it has a prototype gasoline internal combustion engine capable of reaching 50% , a value even higher than that of Diesel engines (which range between 43-45%).

Having a high level of thermal efficiency — taking advantage of the conversion of thermal energy from the chemical reaction of combustion into mechanical energy — is essential to reduce CO2 consumption/emissions. However, to achieve this high value of 50% efficiency, Nissan changed the target of the combustion engine.

This new objective is no longer serving as a vehicle propellant (where it is connected to the wheels) and now serving only as a generator (not connected to the wheels) of energy for an electric traction motor.

A more efficient gasoline engine to serve… electric ones

No wonder, then, that this announcement came under the guise of Nissan's e-POWER (hybrid technology) technology, which already serves models like the Note and will also serve the third-generation Nissan Qashqai.As we have already mentioned on several occasions, Nissan's e-POWER models are fundamentally electric vehicles. However, the electrical energy they need to function does not come from a large, heavy and expensive battery, but from an internal combustion engine that takes on the role of generator. There is still a battery, it is true, but it is much smaller, serving to store the energy produced by the heat engine.

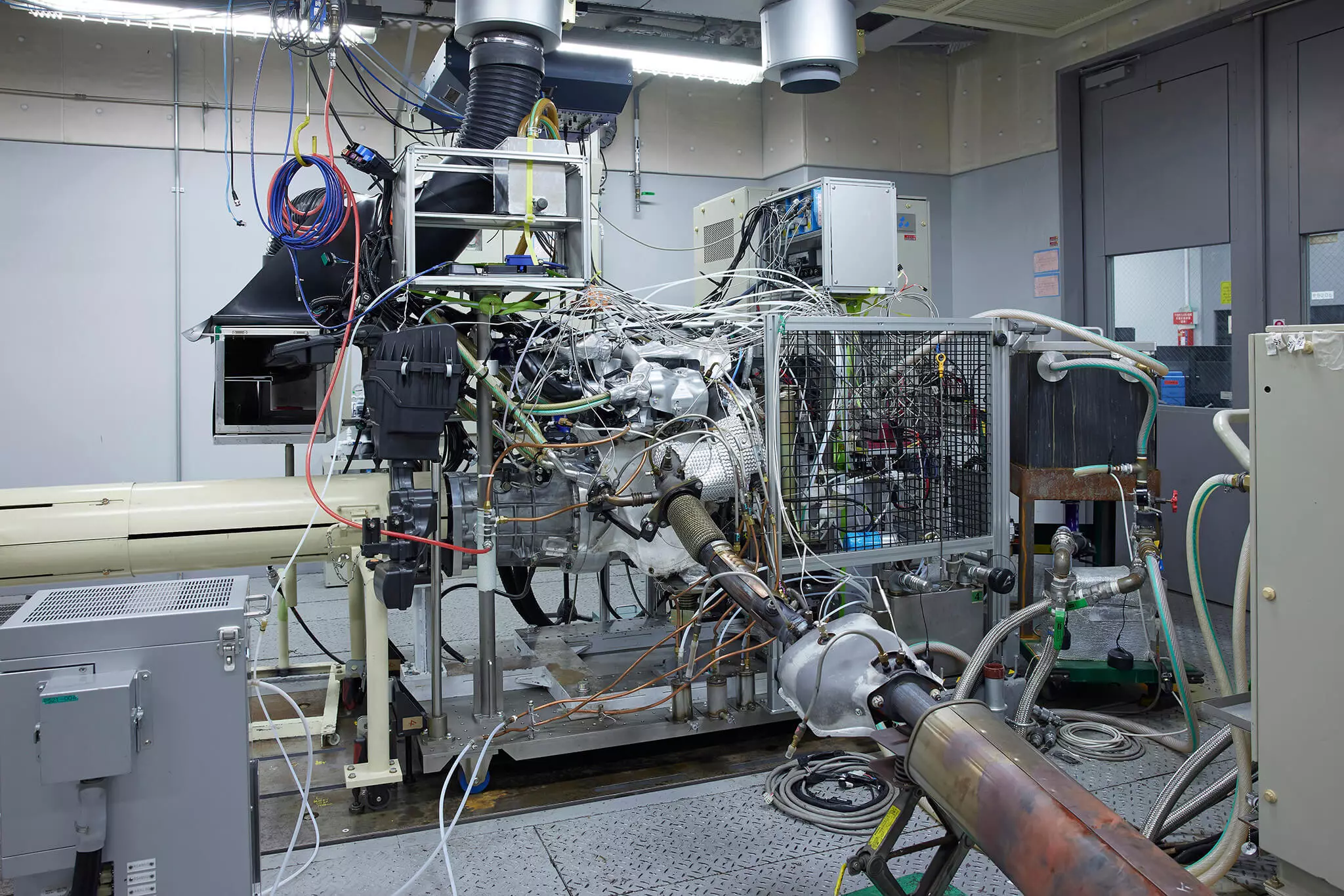

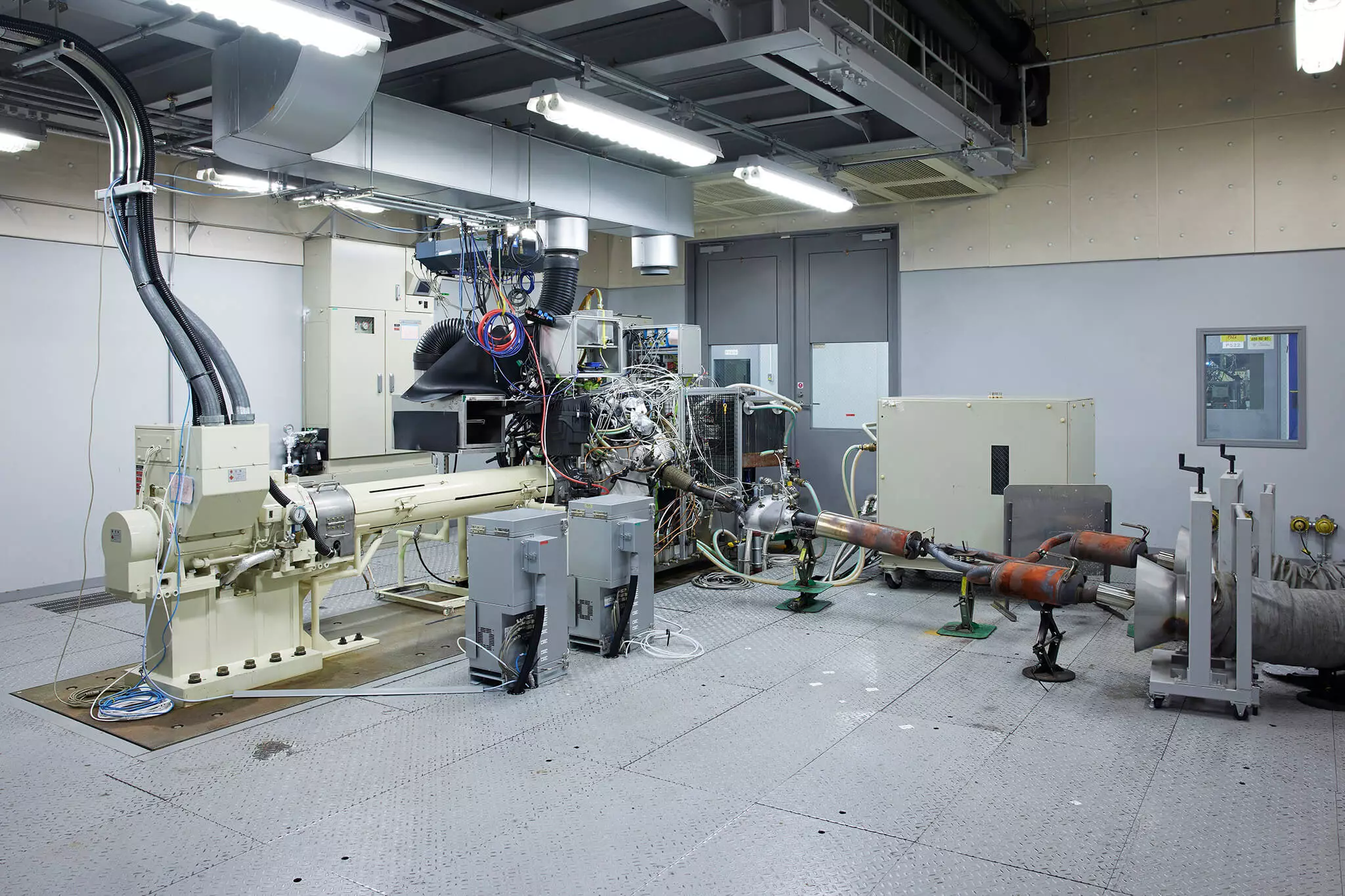

STARC, the prototype engine

Becoming just a generator, it is possible to limit the operation of the heat engine to its most efficient regime of rotations and loads. It is the first step towards achieving 50% thermal efficiency. Nissan now shows the next steps to reach such an ambitious goal, under the development of the next generation of e-POWER technology, having already resulted in a prototype engine, the STARC.

Subscribe to our newsletter

STARC is an acronym for “strong, tumble and appropriately stretched robust ignition channel” — even with this description, we were somewhat at a loss… According to Nissan, we can freely translate this into something like “robust, specifically designed and extended ignition chamber” .

Decoding the meaning of all this, the work of the Nissan engineers has essentially focused on accelerating the intake flow of the fuel-air mixture inside the cylinder during ignition, which will allow a more complete combustion of a mixture of fuel. more dilute fuel air with a higher compression ratio.

Something that has not been possible to achieve in a heat engine that is used as a propeller. It has to respond to constant variations in load and power at each moment (acceleration, deceleration, slopes), which requires compromises in its operating parameters (mixture flow in the cylinder, ignition time and compression ratio). Its efficiency is thus compromised.

All these obstacles disappear when the heat engine becomes a generator, in which it starts to work only in the ideal rotations and loads regime, where it is more efficient (in a much more limited range), allowing, from the outset, lower consumption and emissions.

The results of the first development tests on a multi-cylinder engine are promising. An efficiency of 43% was achieved when using an EGR (exhaust gas recirculation valve) dilution method and 46% by applying a lean air-fuel mixture (ie with a mixture where there is more air than fuel in relation to the ideal mixture for the complete burning of the fuel).

The 50% thermal efficiency of the new STARC engine is achieved when these measures are combined with waste heat recovery technologies and engine running at constant load and speed. It now remains to wait some more time for the introduction of this specialized heat engine.

Toshihiro Hirai, Senior Vice President, Electric Car Engineering Division and Powerplants at Nissan Motor Co. Ltd“Aiming to achieve carbon neutrality in the lifecycle of its products until 2050, Nissan intends to electrify by the beginning of the 2030s all new models launched in the main global markets. Nissan's electrification strategy promotes the development of electric powertrains and high-performance batteries for electric cars, with e-POWER technology representing an important strategic pillar on this path».