One of the positive consequences that we see in the continued use of hybrid and electric cars is the increased longevity of the braking system when compared to a conventional car. This is due to the regenerative braking system – which transforms the kinetic energy of deceleration into electrical energy that is stored in the batteries. Given the system's slowdown effect, it allows both tablets and disks to be less in demand.

In some hybrid or electric cars, the regeneration system can be adjusted for a more or less aggressive brake effect. When in the most aggressive mode it becomes possible to drive in everyday life just using the right pedal, without almost touching the brakes.

But the lack of use of conventional brakes can become a long-term problem. The brake discs are made of steel and this, as we know, easily shows signs of corrosion, impairing its effectiveness by reducing the friction levels between the pads and the disc.

Although less in demand, the conventional braking system will still be needed. Not only when the driver needs to brake harder, but also when they are required by driving assistance systems such as automatic emergency braking.

Steel gives way to aluminum

It is taking into account this new set of needs that Continental - the well-known tire brand and supplier of technological solutions for the automotive industry -, "hid" behind a name as generic as New Wheel Concept (new wheel concept). wheel reinvented.

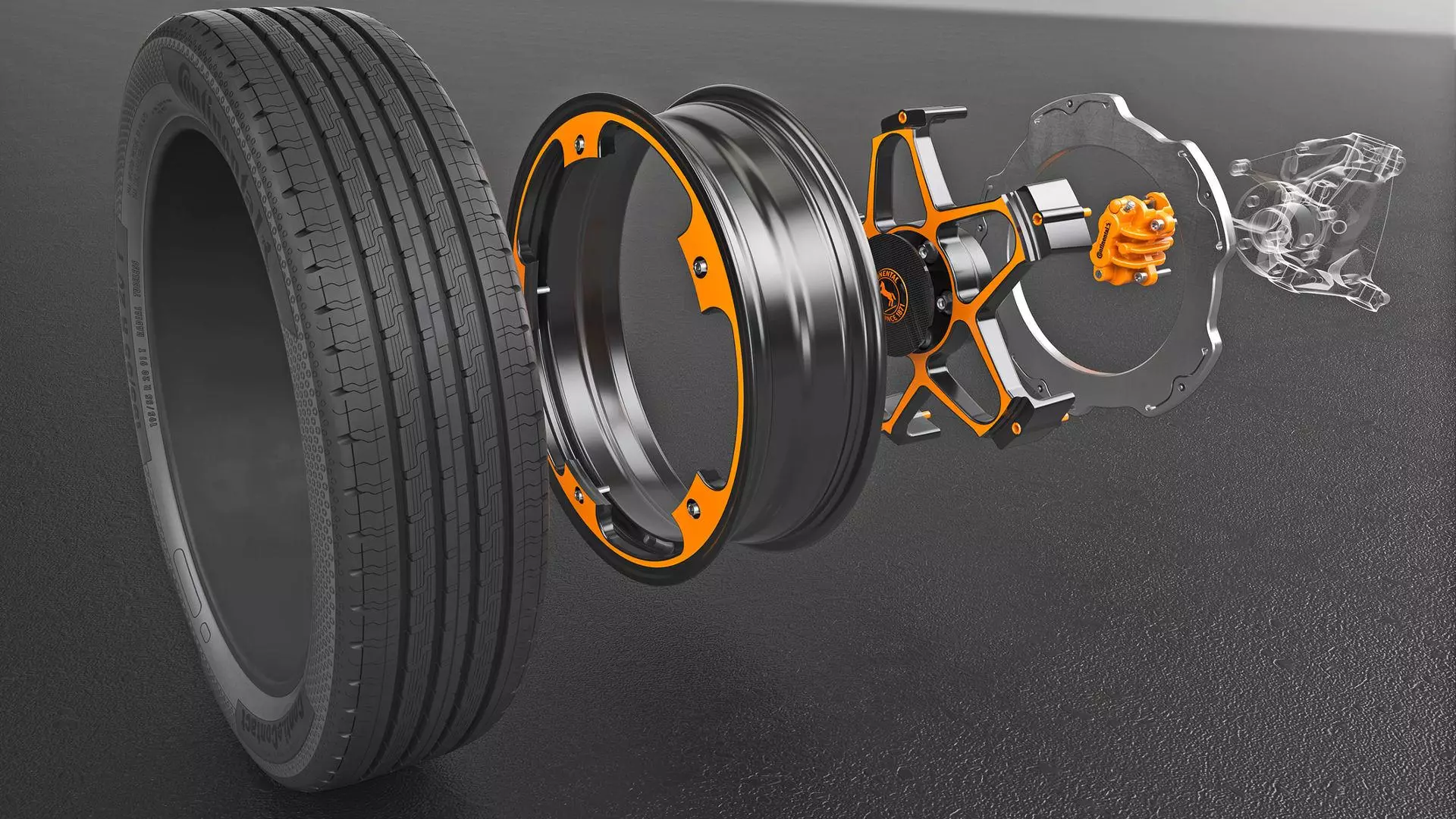

Its solution is based on a new division between the wheel and the axle, and consists of two main parts:

- a star-shaped aluminum inner bracket that is attached to the wheel hub

- the wheel rim that supports the tyre, also in aluminum, and which is fixed to the star support

As you can see, troublesome steel gives way to aluminum . As such, its resistance to corrosion is far superior, with the German brand claiming that the disc can have a service life as long as that of the vehicle itself.

The brake disc also features a different design from the one we know. The disc is bolted to the star support – and not to the wheel hub – and it could well not be called a disc due to its annular shape. This solution allows the disc to grow in diameter, benefiting braking performance.

However, if the disc is fixed to the star support, it means that the surface where the caliper acts resides inside the disc, unlike conventional braking systems. With this solution, Continental also achieves a superior friction area, as the space inside the wheel is optimised.

The advantages of this system are also reflected in the costs for the user, as the disc can have a useful life span as long as that of the car. The system is also lighter than a current wheel-brake assembly and as such we have reduced the weight of unsprung masses, with all the benefits that come with it.

Another advantage refers to the superior leverage provided by the larger diameter of the disc, which allows the caliper to not need to exert as much force on it to achieve the same braking efficiency. And since aluminum is an excellent conductor of heat, the heat generated on the disc during braking is also quickly dissipated.