Mazda continues the development of Skyactiv technology in both petrol and diesel blocks. Discover the latest 1.5 Skyactiv D unit that will debut on the next Mazda 2.

After the 2.2 Skyactiv D block, there is now the little brother, the 1.5 Skyactiv D, which has its debut marked with the future Mazda 2.

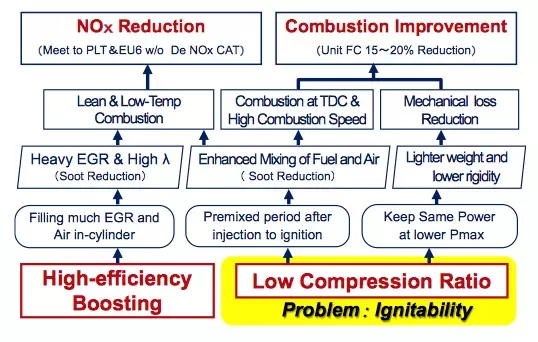

This new engine from Mazda with Skyactiv technology already meets the stringent EURO 6 standards, and does so without any catalysis system. But to achieve these results, Mazda was faced with several problems that limit the potential of Diesel mechanics.

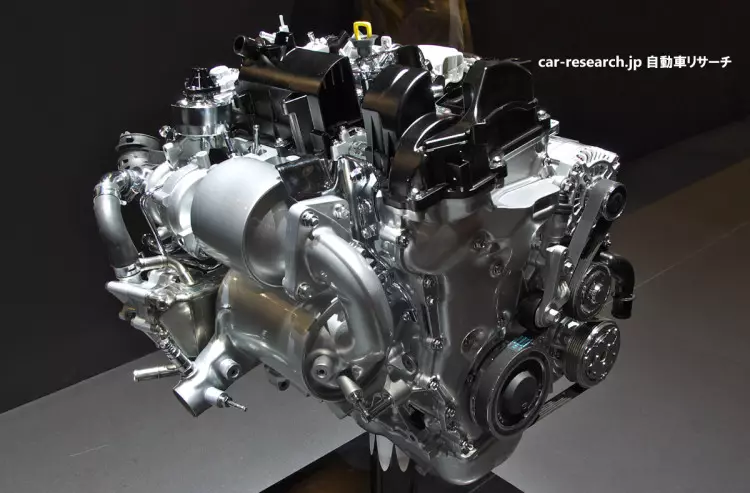

However, the result obtained, using a variable geometry turbocharger and integrated rotation sensor, together with a water-cooled intercooler, fully satisfies the Japanese brand. Second, it will improve the efficiency and response of the 1.5 Diesel block. Mazda believes it will have the lowest consumption diesel engine in its class.

The 1.5 Skyactiv D block presents itself with a displacement of 1497cc and 105 horsepower at 4000rpm, the maximum torque of 250Nm appears as early as 1500rpm and remains constant until close to 2500rpm, all with CO₂ emissions of just 90g/km.

But to reach these values, not everything was rosy and Mazda faced numerous technical problems. Problems that according to the brand were overcome, through the use of the latest technologies. But let's go in parts, with a view to unraveling all the challenges that Mazda overcame to develop this 1.5 Skyactiv D engine.

How was it possible to overcome demanding environmental standards without the need for catalytic treatment?

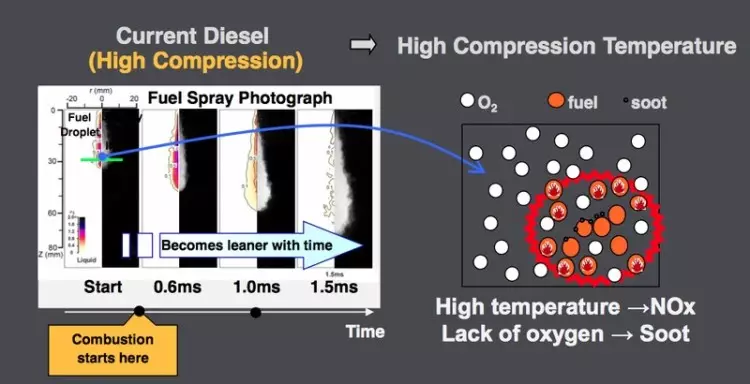

Diesel blocks generally operate at compression rates, much higher than gasoline blocks. This is due to the specificity of diesel combustion, which detonates at high pressures and does not explode like gasoline, but catches fire.

This issue becomes particularly problematic, since due to the high compression ratios, when the piston is at its TDC (top dead center), ignition tends to occur before the total and homogeneous mixture between air and fuel, resulting in the formation of NOx gases and polluting particles. Delaying fuel injection, while helping with temperature and pressure, results in worse economy and therefore higher consumption.

Mazda, aware of these problems, nevertheless decided to bet on reducing the compression ratio of its Diesel Skyactiv blocks, with compression ratios of 14.0:1 – a manifestly low value for a diesel block, since the average is around 16.0: 1. Using this solution, by means of pistons from specific combustion chambers, it was possible to reduce the temperature and pressure in the PMS of the cylinders, thus optimizing the mixture.

With this problem resolved, the fuel economy issue remained to be resolved, so Mazda resorted to the magic of electronics. In other words, injection maps with complex algorithms capable of performing an optimized pre-mix, in a block with a low compression rate. In addition to the beneficial effects on combustion, the reduction in the compression ratio made it possible to reduce the weight of the block, as it is subject to less internal pressure, thus improving consumption and the engine's speed of response.

How did Mazda solve the problem of cold starting and hot auto ignition with a low compression ratio?

These were the other two problems underlying the block's low compression ratio. With a lower compression ratio, it becomes more difficult to build up enough pressure and temperature for the fuel to ignite. On the other hand, when the block is hot, the low compression ratio makes auto-ignition spots difficult for the ECU to manage.

It was due to these issues that Mazda decided to include in the 1.5 Skyactiv D block, the latest Piezo injectors with 12-hole nozzles, allowing a variety of injection and operation situations in very short intervals, managing to perform a maximum of 9 injections per cycle , allowing to control the concentration of the mixture, solving the problem of cold start.

In addition to the 3 basic injection patterns (pre-injection, main injection and post-injection) these Piezo injectors can perform a number of different patterns according to atmospheric conditions and engine load.

Auto-ignition was resolved, using variable valve timing. The exhaust valves open a little during the intake phase, allowing the exhaust gases to be recycled back to the combustion chamber, increasing the temperature, without creating pressure points, since in Diesel blocks the temperature rises in the combustion chamber. combustion stabilizes ignition, thus compensating for the use of high compression ratios, which in turn generate pressure spikes that are difficult to control.