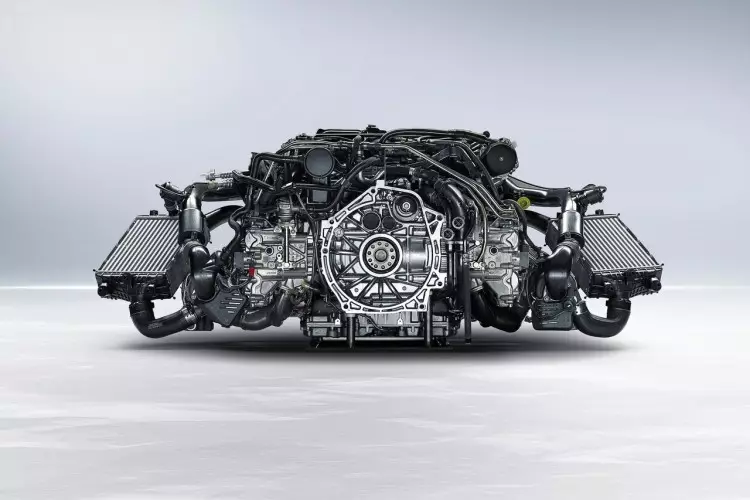

Porsche has taken the lead in the race for the "holy grail" of top technology in internal combustion engines: achieving the much envied variable compression ratio. Know the differences.

The result of a partnership between Porsche engineers and engineering company Hilite International, Porsche appears to have arrived at a viable solution to achieve the best of both worlds in supercharged engines.

Porsche is studying the possibility of using variable compression to increase the efficiency of turbo engines at low revs, saying goodbye forever to 'turbo lag', without the need for attached systems so that the turbocharger's turbine is always rotating at high speeds. rotations.

SEE ALSO: This is the bonus that Porsche workers will receive

The reason why this technology has aroused so much interest, leading to the channeling of resources, is now gaining greater preponderance with the need to increase the efficiency of internal combustion engines. Before we see them leave the automotive scene altogether, with the “downsizing virus” all over the place, the quickest and lowest-cost solution was to resort to supercharging through turbochargers. But not everything represents efficiency when we involve the use of a turbocharger in this equation.

No matter how much efficiency it is possible to extract from these mechanics, there are structural limitations and for the cylinders to be able to fill with the extra air volume coming from the turbo compressor, the compression ratio of these engines must be significantly lower than that of engines otherwise, the self-detonation phenomenon, which is catastrophic for any engine, would be a constant.

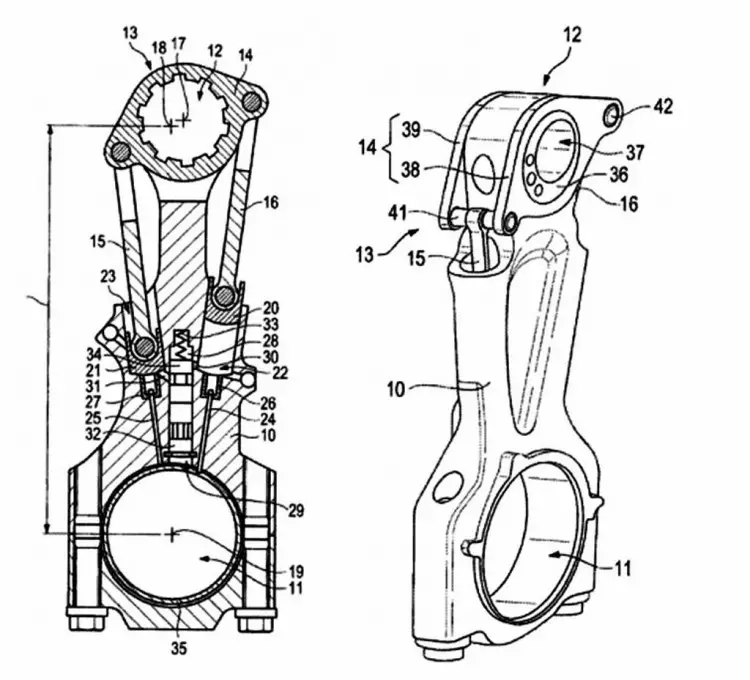

What is the difference? A new connecting rod design

The lethargic state characteristic of turbo engines at low revs is well known and instead of resorting to extra plumbing, called “Anti-Lag Systems” (which briefly use “bypass valves” in the exhaust manifold) Porsche comes up with a new design of connecting rods. These new connecting rods contain hydraulic actuators and allow you to vary the position of the pistons, thus achieving the so desirable variable compression ratio.

With this solution, Porsche manages to make the apathy of the turbo at low revs no longer evident, since with this technology it is possible to vary the position of the pistons to the high compression position, increasing the efficiency at low rpm. and that the engine responds like an atmospheric block.

NOT TO BE MISSED: The Porsche 911 GT3 RS in action

This technology will improve consumption and the power curve. Once the exhaust gases are able to spin the turbocharger turbine, the pistons are lowered to the low compression ratio position so that the turbo compressor delivers the extra air volume at the maximum pressure the turbo is capable of. , generating more power, without the risk of auto detonation and illogical ignition advance calculations by the ECU.

In the design that we present to you, Porsche decided to provide the connecting rod with a low pressure solenoid valve, which, by varying the oil pressure between the hydraulic actuators, makes the control rods move the bearing on top of the connecting rod automatically. This downward or upward movement varies the piston in two positions: a higher one for a higher compression ratio and a lower one for a lower compression ratio.

Porsche guarantees that verifying the commercial and mechanical viability of this technology, it will liberalize the patent so that it can be used by the market.

Be sure to follow us on Facebook and Instagram