In the not too distant future , Hyundai may start producing cars using carbon fiber reinforced polymers (CFRP). An innovation that could help control the weight of your models and increase occupant safety.

An information that became public thanks to the publication of the patent registration in the U.S.A.

Like?

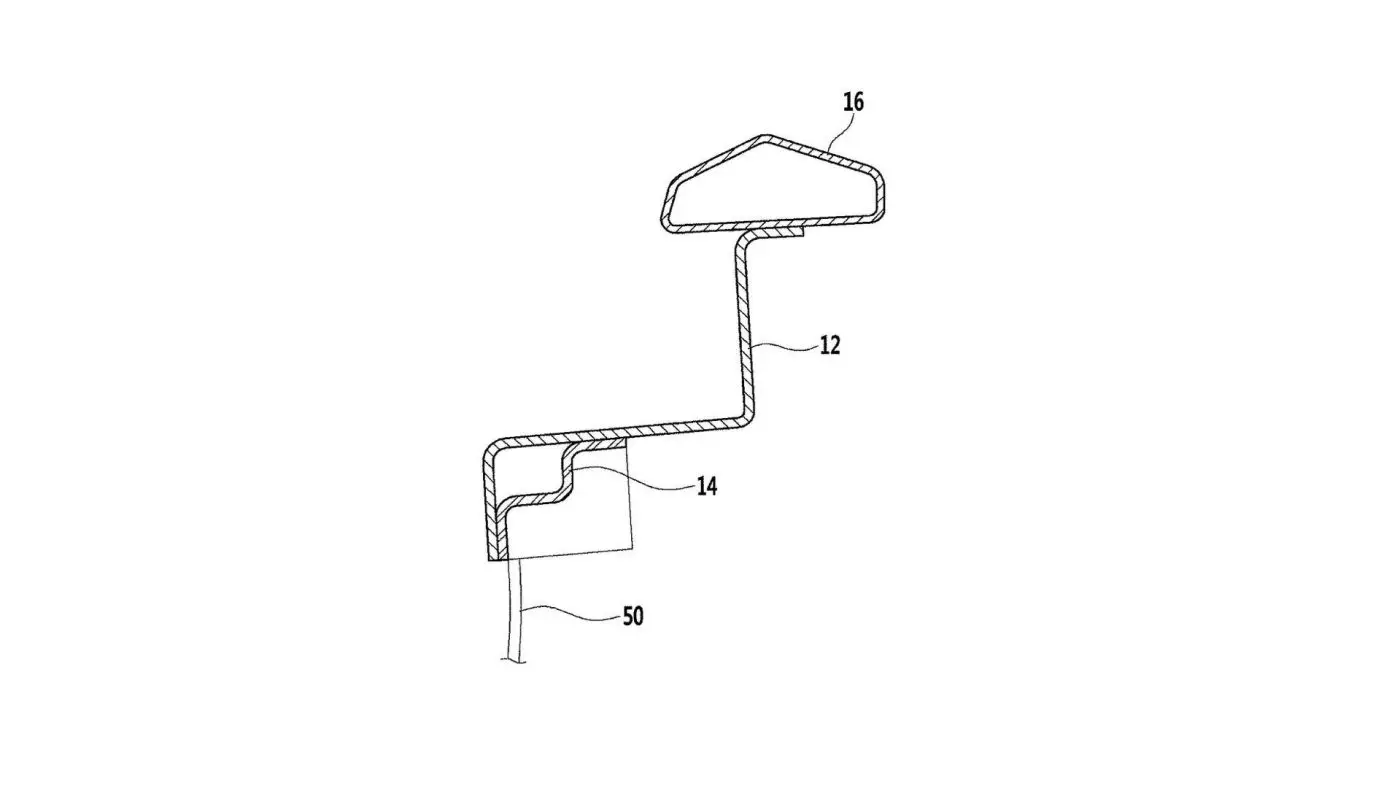

In the images, it is possible to understand where and how Hyundai intends to use the CFRP:

The Korean brand intends to produce the front sections of the chassis, referring to the A-pillar and the separation between the cabin and the engine, in this composite material. Brands typically use aluminum and reinforced steel in the construction of this section.

In addition to reducing chassis weight and increasing torsional strength, the use of CFRP can help brand designers design the A-pillars with greater freedom. Currently, oversized A-pillars (to ensure the safety of occupants) is one of the biggest obstacles in the design of an automobile.

Braided carbon

Braided carbon (or braided carbon in Portuguese), may be how Hyundai will unite these sections. It is the same technique used by Lexus to produce the LFA chassis.Using a computer-controlled loom, the carbon fiber is woven together to form a single piece.

A surprise?

Hyundai is the only brand in the world that produces the steel for its own cars, so the use of new materials may come as a surprise. An advantage that the brand has taken advantage of in recent years, allowing the production of various components under superior scrutiny and to specific orders.

In addition to producing steel for the automotive sector, Hyundai is also one of the few producers in the world with the capacity to produce high-strength steel for superships and oil tankers.