At the Geneva Motor Show that should have taken place, the new, North American and ballistic would be publicly revealed Czinger 21C . Yes, it's another hyper-sport with overwhelming numbers of power, acceleration and top speed.

Although, nowadays, a new hyper-sport seems to appear every week, there is a lot to highlight in the Czinger 21C, like its design, marked by a very narrow cockpit. Only possible due to the arrangement of the two seats, in a row (tandem) and not side by side. Result: The 21C joins the few models that offer a central driving position.

In terms of performance, the highlight was the promise of just 29s to fulfill the ambitious 0-400 km/h-0, a figure lower than the 31.49s achieved by the Koenigsegg Regera. To understand how this could be possible, the best thing is to start with your numbers...

1250 kg or less

We start with its low mass, a low 1250 kg for the road version, even a lower 1218 kg for the version focused on circuits that can be reduced to 1165 kg, if we only use it exclusively on circuits.

1250 kg is a very low value in this universe of hyper-sports, and for more accompanied by 1250 hp of maximum combined power. Combined? Yes, because the Czinger 21C is also a hybrid vehicle, integrating three electric motors: two on the front axle, ensuring all-wheel drive and torque vectoring, while the third is next to the combustion engine, serving as a generator.

In white the road version, in blue (and with a prominent rear wing), the circuit version

Powering the electric motors is a small lithium titanate battery of just 1 kWh, an unusual choice in the automotive world (some versions of the Mitsubishi i-Miev came with this type of battery), but faster than the ion-ion ones. lithium when it comes to charging.

2.88 V8

But it is the self-designed combustion engine, however, that deserves all the highlights. It is a compact Bi-turbo V8 with just 2.88 l, flat crankshaft and a limiter at… 11,000 rpm(!) — another one that breaks the 10,000 rpm barrier, to more supercharged, joining the atmospheric V12s of the Valkyrie and Gordon Murray's T.50.

The maximum power of this 2.88 V8 is 950 hp at 10,500 rpm and 746 Nm of torque , with the electric machine supplying the missing horses to reach the announced maximum combined power 1250 hp. Czinger also refers that its bi-turbo V8, by achieving 329 hp/l, is also the production engine that has more specific power.

Subscribe to our newsletter

After all, 1250 hp for 1250 kg this is a creature with a weight/power ratio of just 1 kg per horse — the performance could be nothing more than ballistic…

Is fast? No doubt

fugitives 1.9s and we are already at 100 km/h; 8.3s it's enough to complete the 402 m of a classic drag race; from 0 to 300 km/h and back to 0 km/h, only 15s ; and, as we have already mentioned, Czinger only announces 29s to do the 0-400 km/h-0, a lower figure than the record holder Regera.

The maximum speed advertised is 432 km/h for the road version, with the circuit version “staying” at 380 km/h — blame (in part) the more than 790 kg of downforce at 250 km/h, compared to 250 kg at same speed as the road version.

Finally, the transmission is of the transaxle (transaxle) type with the gearbox being of the sequential type with seven speeds. Like the engine, the transmission is also of its own design.

beyond the numbers

However, beyond the impressive numbers, it is the way in which the Czinger 21C (short for 21st Century or 21st Century) was conceived and will be produced that catches the eye. Although the production Czinger 21C has only just been unveiled, it was actually 2017 that we saw it for the first time, still as a prototype, and called the Divergent Blade.

Divergent is the company that developed the technologies needed to produce the Czinger 21C. Among them are additive manufacturing, more commonly known as 3D printing; and the design of the assembly line, or rather, the assembly cell of the 21C, is also hers, but we'll be there soon…

It's no coincidence that behind Divergent we find, in the CEO roles, Kevin Czinger, the founder and CEO of… Czinger.

3D printing

Additive manufacturing or 3D printing is a technology with a high disruptive potential when applied to automobile production (and beyond), and the 21C thus becomes the first production car (although there are only 80 units in total) where we can see extensive parts of its structure and chassis being obtained in this way.

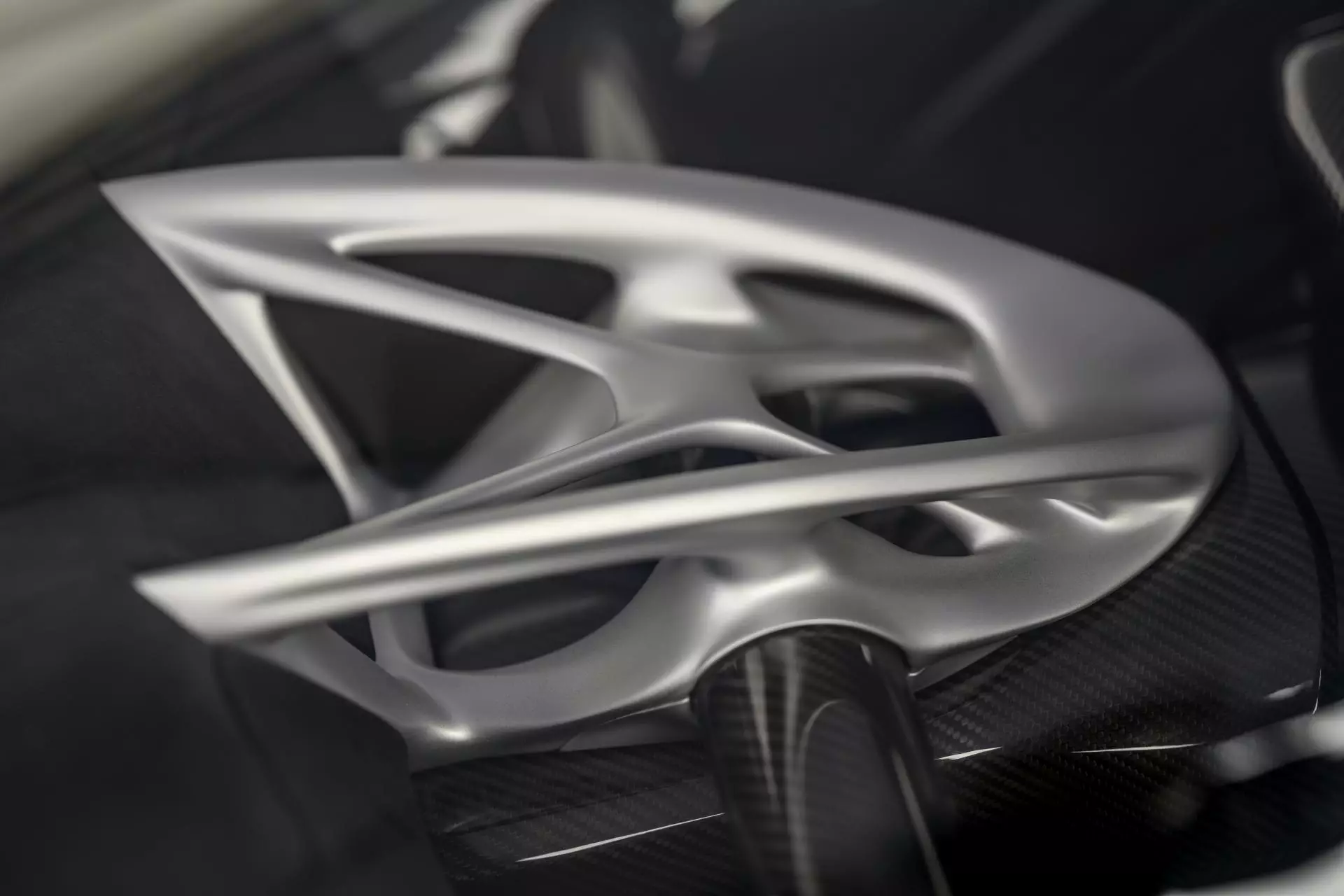

3D printing on the 21C is used on complex shaped parts, based on an aluminum alloy — the materials most used on the 21C are aluminum, carbon fiber and titanium — which are impossible to produce using conventional production methods, or then requiring two or more pieces (later joined together) to achieve the same function from one piece.

Perhaps one of the components where we see this technology being used most dramatically is the organic and complex suspension triangles of the Czinger 21C, where the arms are hollow and of varying thickness — by allowing for “impossible” shapes, 3D printing enables structural optimization of any component beyond what was possible until now, using less material, reducing waste and not least, weight.

In addition to 3D printing, the Czinger 21C also uses conventional production methods, for example, it also includes extruded aluminum parts.

Assembly Cell Line

The novelties are not limited to 3D printing, the 21C's production line is also unconventional. Divergent says it does not have a production line, but a production cell. That is, instead of seeing a vehicle taking shape along a corridor or corridors in a factory, in this case we see it concentrated in a space of 17 m by 17 m (much more compact than the space occupied by machine tools in a line of assembly), a group of robot arms, capable of moving 2 m per second, assembling the “skeleton” of the 21C.

According to Lukas Czinger, director of automation and manufacturing (and son of Kevin Czinger), with this system it is no longer necessary to have machine tools: “it is not based on an assembly line, but on an assembly cell. And it's done with a precision that's not seen in the auto industry.”

Each of these cells has the capacity to assemble 10,000 vehicle structures per year at a much lower cost: just three million dollars, against more than 500 million dollars for assembling a traditional structure/bodywork.

Also according to Lukas, in less than an hour, these robots can assemble the entire structure of the Czinger 21C, holding it in different positions, while the various parts are installed.

In addition, this solution is extremely flexible, allowing robots to assemble completely different vehicles in a short period of time, obeying other orders given in the schedule — something that is not feasible on a conventional production line either.

Top Gear had the opportunity to visit Czinger's factory, giving us a better understanding of the technologies that the 21C contains, both in terms of 3D printing and the way in which it is assembled.

How much does it cost?

Only 80 units will be produced — 55 units for the road model and 25 for the circuit model — and the base price, excluding taxes, is 1.7 million dollars, approximately 1.53 million euros.